An additive manufacturing facility at the Naval Undersea Warfare Center-Division Keyport in Washington has remained operational during the COVID-19 pandemic and created personal protective equipment for local civilian medical workers.

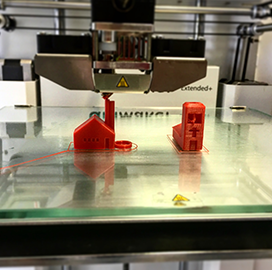

NUWC Keyport said Friday its rapid prototyping team used the 3D printing process in efforts to accelerate the development and production of PPE as well as ship and submarine components.

"Each day the team is able to prototype new designs, develop new manufacturing processes, and deliver PPE hardware," said Bryce Weber, division technology manager at NUWC Keyport's rapid prototyping and fabrication technology division.

Weber added that the work center offers a lot of space between additive manufacturing printers, allowing workers to practice social distancing, and requires team communication to ensure compliance with cleaning protocols.